I Overview

Boiler water treatment refers to a variety of techniques and devices used to eliminate dissolved substances, including oxygen and minerals, from boiler feed water.

II Applications

Corrosion and reduction in heat transfer in a boiler can occur in the forms of chemical attack of the wetted surfaces, such as pitting and mineral deposition. Mineral deposition, also known as scaling, occurs when dissolved minerals precipitate out of solution, and can cause a loss of efficiency. Pitting occurs when dissolved oxygen reacts with boiler tube walls, and can force a shutdown of the boiler. The purpose of water treatment, then, is to prevent corrosion and deposition of minerals from occurring on the wetted surfaces within boilers.

III Equipment Options

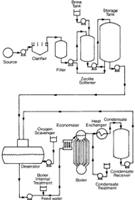

Water treatment options can be broadly categorized into internal and external treatments.

External treatments include clarification, filtration, softening, dealkalization, and deaeration. Clarification and filtration remove suspended solids, including mud, silt, and bacteria, by either chemical or mechanical means. Softening removes dissolved minerals. Dealkalization reduces the pH of softened water. Deaeration removes oxygen and other non-condensable gases.

Internal treatments include chemical additions and blowdown. Chemical additions include oxygen scavengers, hydroxides, phosphates, polymers, chelants, and amines, which all serve to reinforce various external treatments applied to the boiler water. Many of these chemicals produce solids which must then be removed in the blowdown process.

IV Resources

1. Equipment Manufacturer Database

2. Boiler Burner Consortium

V Photo